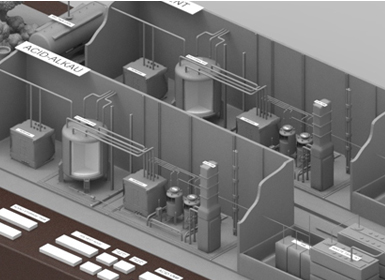

With Total Engineering Services from the manufacturing of highly concentrated chemicals to their storage, supply or transport via lines, Fluoro Tech maximizes customer satisfaction.

-

Transport of chemicals Tank Lorry & Container

Transport of chemicals Tank Lorry & Container

The tank lorry receives chemicals from the chemical manufacturer and transports them in accordance with the laws concerning road transport and the Chemical Substance Management Act.

-

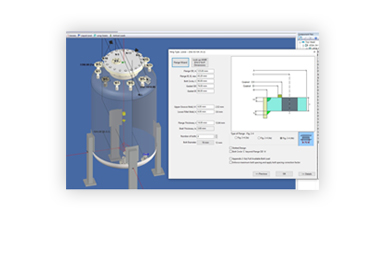

Storage and transport Storage Tank

Storage and transport Storage Tank

A device that stores and supplies large quantities of chemicals received.

-

Mixing Mixing Tank

Mixing Mixing Tank

A device needed for diluting or mixing the supplied chemicals to the precise concentration required by the mass production facility.

-

Supply Supply Tank

Supply Supply Tank

A device that continuously supplies the chemicals to the final mass production facility at a constant pressure and volume.

-

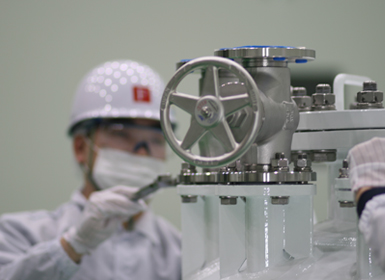

Installation and

Installation and

maintenance Leak Sensor

A sensor that can detect any chemical leaks. It is also used for maintenance such as the diagnosis of the tank or leaks.